Mistakes to Avoid When Choosing High Voltage X-Ray Source Manufacturers

Selecting the right X-ray source manufacturers is a decision that can significantly impact operational efficiency, safety, and imaging precision across industrial and medical applications. A misstep in this selection process can lead to inconsistent performance, higher maintenance costs, or even operational hazards. Many businesses underestimate the complexity involved, assuming all manufacturers offer similar quality or support. However, the differences in technology, reliability, and service capabilities are substantial.

This blog highlights common mistakes organizations make when choosing high-voltage X-ray source manufacturers and offers practical guidance to avoid them. By understanding these pitfalls, decision-makers can ensure that their investment delivers long-term value, enhanced productivity, and uncompromised safety.

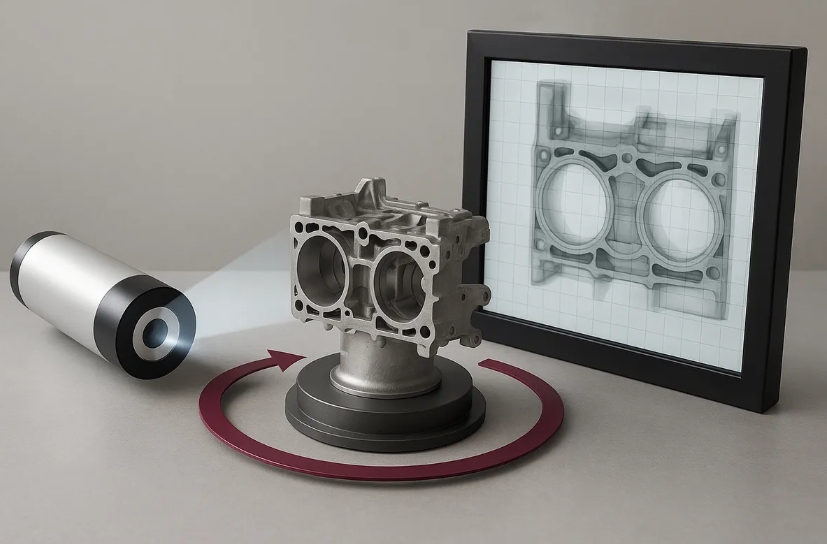

1. Overlooking Technical Specifications and Compatibility

When selecting a high-voltage X-ray source, understanding technical specifications and system compatibility is critical. Overlooking voltage requirements, integration needs, and environmental constraints can compromise imaging accuracy and shorten equipment life.

- Neglecting Voltage and Output Requirements: Selecting a source without verifying the exact voltage and output needed for your systems can lead to inefficient imaging or equipment failure. Every application demands specific energy levels, and ignoring these requirements can compromise accuracy and reduce the lifespan of both the X-ray source and connected equipment.

- Ignoring Integration Capabilities: Many organizations focus on the device alone and overlook compatibility with existing software, detectors, and control systems. Incompatible systems result in frequent troubleshooting, delayed operations, and potential data inaccuracies, making integration assessment critical.

- Underestimating Environmental and Operational Constraints: Environmental factors such as temperature, humidity, and operational load directly influence performance. Failing to consider these constraints during selection can lead to premature component degradation and inconsistent output, which can affect the quality of imaging results.

2. Choosing Based on Price Alone

Focusing exclusively on cost can be a costly mistake. While low-priced options may appear attractive, they often come with hidden expenses, reduced durability, and limited support.

- Prioritizing Low-Cost Options Over Quality: A common mistake is prioritizing initial cost savings over performance and durability. While a lower-priced option may seem attractive, it often comes with hidden costs, including frequent maintenance, shorter component life, and higher operational risk.

- Ignoring Total Cost of Ownership: The total cost of ownership (TCO) includes maintenance, spare parts, energy consumption, and service support. Focusing solely on the purchase price without considering long-term operational expenses can erode ROI and lead to costly replacements sooner than anticipated.

- Failing to Evaluate Value-Added Services: Manufacturers offering extended warranties, training, and technical support provide tangible value beyond the initial product. Disregarding these services in favor of cost alone can compromise operational reliability and reduce overall efficiency.

3. Overlooking Manufacturer Reputation and Support

The credibility and support offered by a manufacturer are as important as the technology itself. Overlooking credentials, certifications, and real-world performance feedback can result in sourcing from unreliable providers.

- Neglecting Industry Credentials and Certifications: A manufacturer’s reputation, track record, and industry certifications are crucial indicators of quality and reliability. Overlooking these aspects may lead to sourcing from companies that lack robust quality control processes, increasing the likelihood of performance inconsistencies.

- Ignoring Post-Sale Support and Service Capabilities: Even high-quality X-ray sources require maintenance and troubleshooting. Choosing a manufacturer without adequate post-sale support can result in extended downtime and operational disruption, negatively affecting productivity.

- Not Checking Customer Feedback and Case Studies: Customer testimonials, case studies, and independent reviews provide insight into real-world performance. Ignoring these resources may lead to choosing a manufacturer that does not meet the operational or technical expectations of your specific application.

See also: The Instant Meme Machine: How AI is Revolutionizing Internet Humor

4. Failing to Consider Technological Advancements

High-voltage X-ray technology evolves rapidly, and relying on outdated designs can limit imaging quality, energy efficiency, and system longevity.

- Selecting Outdated Designs: Technology in high-voltage X-ray sources evolves rapidly. Relying on outdated models can limit imaging resolution, efficiency, and system longevity. Ensuring that the manufacturer provides modern, innovative solutions is essential for maintaining competitiveness.

- Overlooking Energy Efficiency and Safety Enhancements: High-voltage X-ray source manufacturers integrate features such as optimized cooling systems, automated monitoring, and energy-efficient designs. Failing to assess these advancements can result in higher energy costs, safety risks, and reduced reliability.

- Not Prioritizing Scalability and Future-Proofing: Equipment requirements often grow with operational demand. Ignoring scalability options and future-proof features can force premature upgrades or replacements, increasing both downtime and costs.

5. Neglecting Operational Training and Compliance

Even the most advanced equipment requires knowledgeable operators to perform effectively. Assuming minimal training, ignoring safety regulations, or overlooking documentation can lead to mishandling, inaccurate imaging results, and potential hazards.

- Assuming Minimal Training Is Sufficient: Proper operation of high-voltage X-ray sources requires specialized training. Neglecting this requirement can lead to mishandling, inaccurate imaging results, and potential safety hazards. Manufacturers providing comprehensive training ensure staff can operate equipment efficiently and safely.

- Ignoring Safety and Regulatory Compliance: High-voltage equipment is subject to strict safety standards. Failing to confirm that the manufacturer adheres to these standards can expose the organization to regulatory risks and endanger personnel.

- Overlooking Documentation and User Guidelines: Detailed manuals, troubleshooting guides, and operational protocols are essential for safe and efficient usage. Disregarding these resources can result in operational errors and increased maintenance issues over time.

Final Thoughts

Avoiding mistakes when choosing X-ray source manufacturers is essential to ensure optimal performance, safety, and long-term cost efficiency. Organizations should carefully evaluate technical specifications, manufacturer reputation, service capabilities, technological advancements, and operational compliance. Equally important is selecting a high-voltage generator solution that complements the X-ray source, ensuring seamless performance and consistent results. By approaching procurement with a comprehensive and informed strategy, businesses can mitigate risks, maximize efficiency, and maintain high standards in imaging operations.

For those seeking expert guidance and advanced, reliable solutions in the high-voltage X-ray domain, VJ X-Ray provides tailored expertise, cutting-edge technology, and innovative products specifically designed to address a wide range of industrial and medical requirements. Their solutions prioritize performance, safety, and long-term operational efficiency, ensuring that one can achieve precise imaging results, reduce downtime, and confidently meet the evolving demands of modern inspection and diagnostic applications.